The Ford Cologne Electric Vehicle Center has officially opened following a $2bn investment to transform the historic plant, founded in 1930.

The plant will be Ford’s first carbon neutral vehicle assembly plant globally, an important milestone on Ford’s Road to Better sustainability plan and the company’s commitment to reach carbon neutrality across its entire European footprint of facilities, logistics and direct suppliers by 2035.

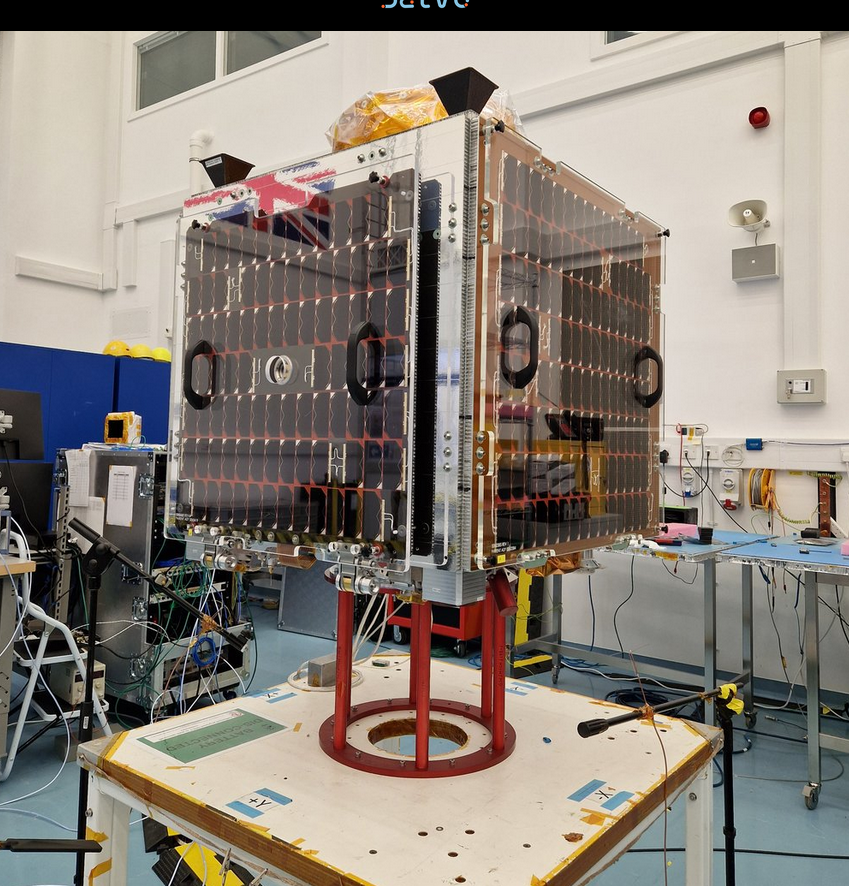

To achieve carbon neutrality, Ford will reduce the use of energy and emissions in the plant by the installation of new processes, machinery, and technologies. All electricity and natural gas required to operate the facility is carbon neutral based on being 100 per cent certified renewable electricity and biomethane.

The heat required to warm the facility and processes is carbon neutral, as the local energy provider will offset the corresponding emissions from the assembly plant on behalf of Ford. The heat is generated by an external power plant and waste incineration plant and provided through a dedicated steam network to Ford.

The technological upgrade of the Ford Cologne EV Center is accompanied by an ecological improvement of biodiversity and the ecological balance of the existing factory greenspace.

Designed to be efficient, the 125-hectare site is equipped with a brand-new production line, battery assembly and state-of-the-art tooling and automation, enabling an annual production capacity of over 250,000 EVs. The Ford Explorer will be the first electric vehicle to be produced in Cologne, followed by a second electric vehicle, a sports crossover.

Latest News

-

Chelsea FC becomes first Premier League club to receive dedicated epilepsy awareness training

-

Car brand hands £100,000 to UK temperate rainforest charity

-

Health firm supports older LGBTQ+ community

-

Good causes across Wales share £600,000 in building society funding

-

Pub firm partners with mental health charity for next two years

-

Home improvement platform names next charity partner

© 2019 Perspective Publishing Privacy & Cookies

Recent Stories