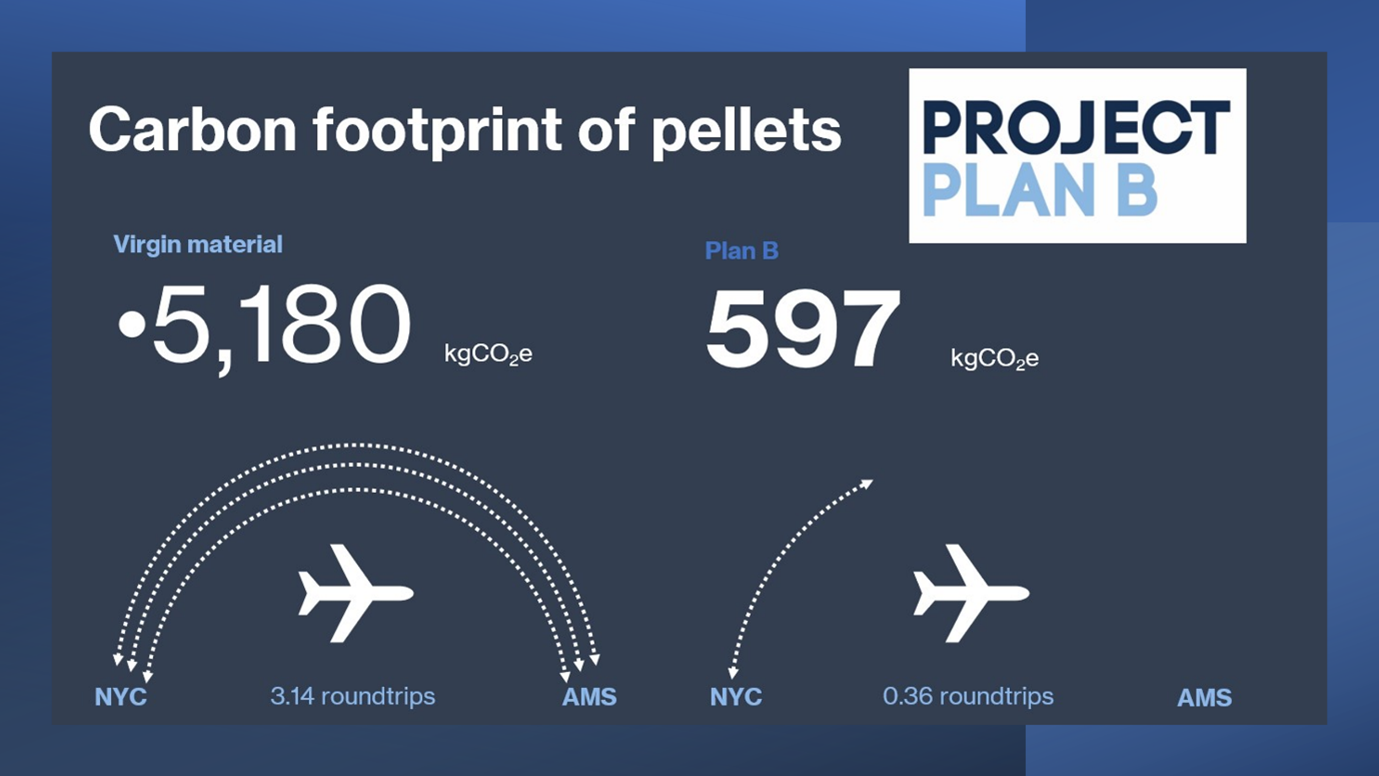

Polyester textiles have been successfully recycled back into raw material as part of a joint venture between Project Plan B and the Salvation Army.

Project Re:claim, between corporate wear specialists Project Plan B and Salvation Army Trading Company (SATCoL,) has also unveiled plans for the first commercial-scale, post-consumer polyester recycling plant.

Based on plastic bottle recycling, the plant will be located at a SATCoL Processing Centre at Kettering, and the new plant will recycle around 2,500 tonnes in its first year, rising to 5,000 tonnes in its second year. To maximise the volume and potential of the polyester recycling, SATCoL cannot rely on clothing bank donations alone, so are searching for corporate partners to commit to donating 100 pe cent polyester textiles now.

Tim Cross, CEO at Project Plan B: “We need a seismic change in how garments are designed and produced. Polyester textile recycling is one of the biggest opportunities to reduce the harmful impact of producing garments and this new technology is the first proven commercial scale system that has been designed to cope with the challenges of recycling post-consumer clothing.”

SATCoL already has the UK’s only automated textile sorting facility, Fibersort. Based at the charity’s purpose-built Processing Centre in Kettering, Fibersort automatically identifies and sorts second-hand textiles by fibre type and is the first step in textile-to-textile recycling. This additional new technology is the next step towards SATCoL’s ambition to create the UK’s first fibre farm, with the aim of massively scaling up textile-to-textile recycling of all types of materials. This presents a huge opportunity for the fashion circular economy.

Latest News

-

Children’s Society director to take charge of Premier League club’s foundation

-

Chelsea FC becomes first Premier League club to receive dedicated epilepsy awareness training

-

Car brand hands £100,000 to UK temperate rainforest charity

-

Health firm supports older LGBTQ+ community

-

Good causes across Wales share £600,000 in building society funding

-

Pub firm partners with mental health charity for next two years

© 2019 Perspective Publishing Privacy & Cookies

Recent Stories